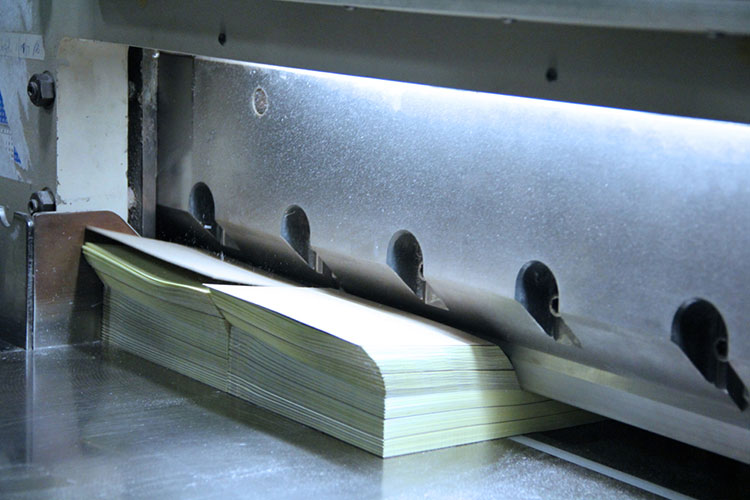

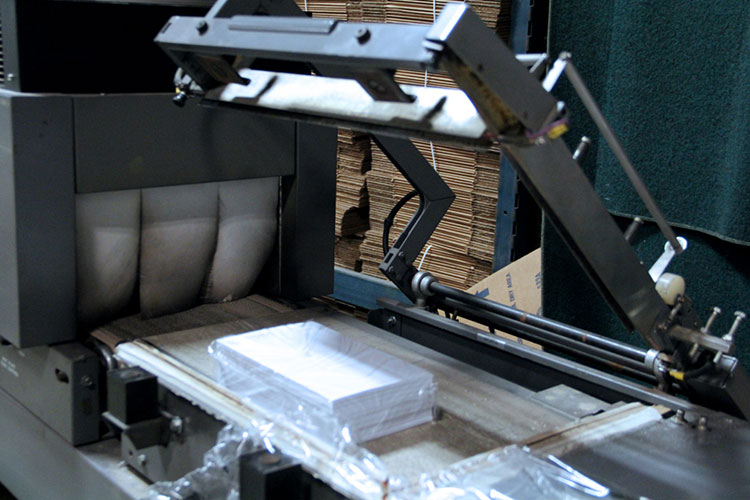

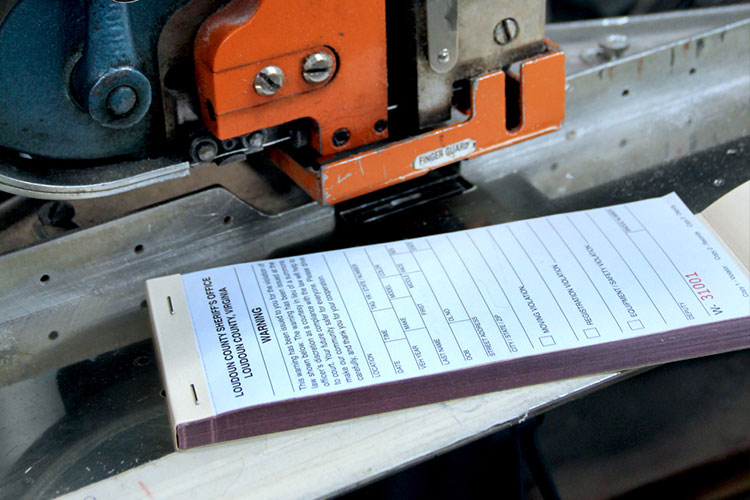

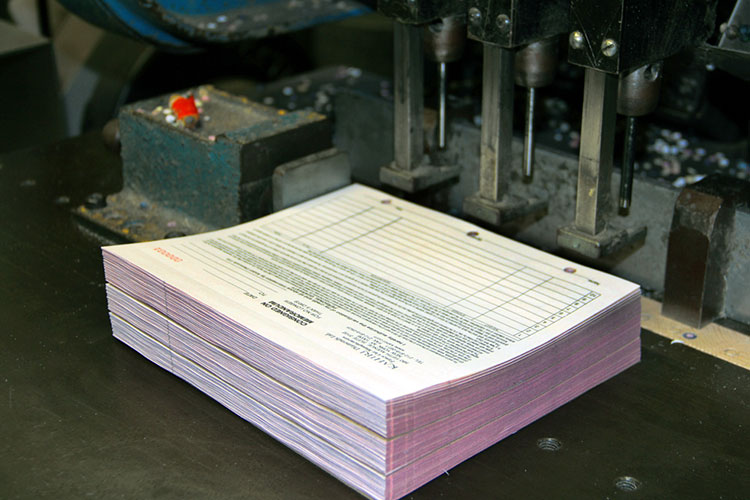

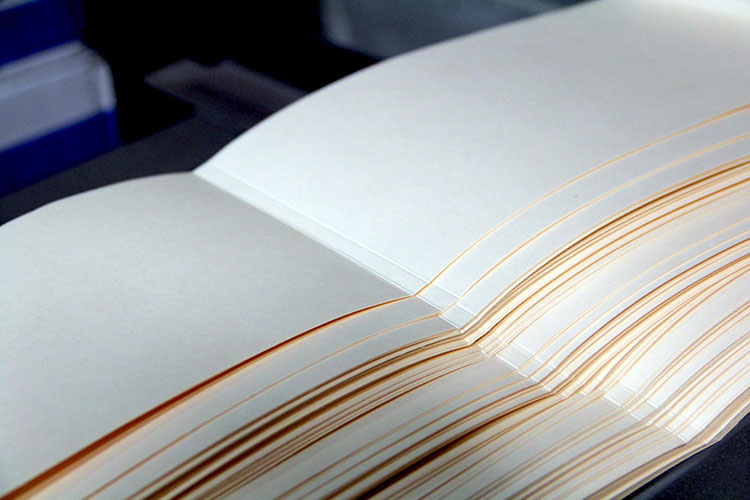

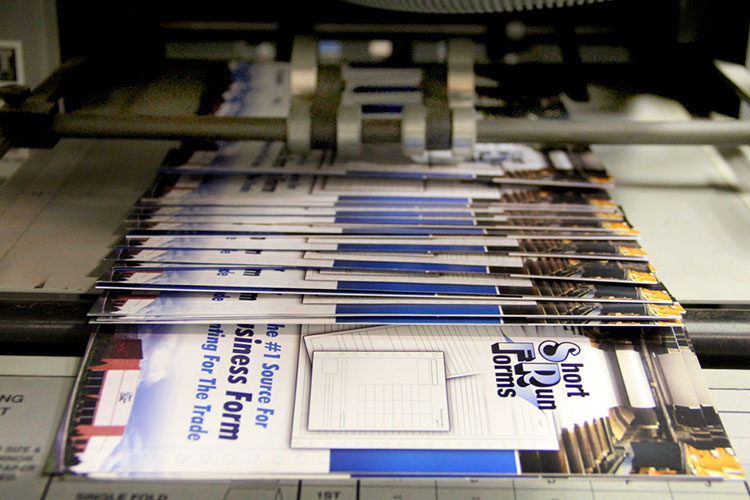

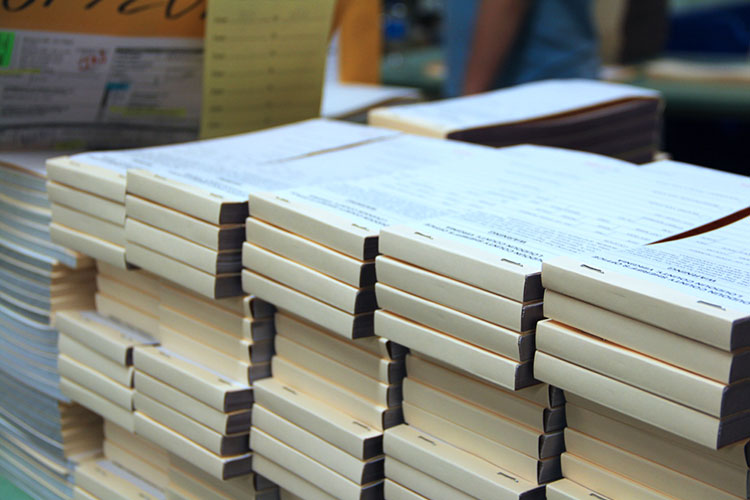

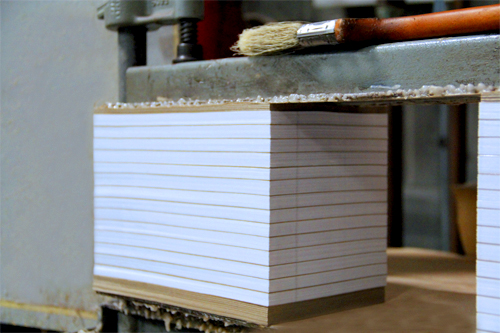

Short Run Forms has a long history of providing commercial printing and bindery services for various industries. Three decades of experience to be exact. Short Run Forms operates the latest equipment and employs skilled printing pressmen to precisely cut, shrink, stitch, hole drill, crease or fold your finished product.

No matter what type of job you are printing or how many, Short Run Forms will provide the care and attention to detail your project deserves. The bindery services department is the best in the industry. Need some customized finishing out of the ordinary? No problem. Thousands of jobs have crossed our printing path. The Short Run Forms bindery department takes great care in knowing your clients final product will be a reflection on YOU. We will do our best to make you look great.